Page 413 - Peterson 85 Years and Going Strong

P. 413

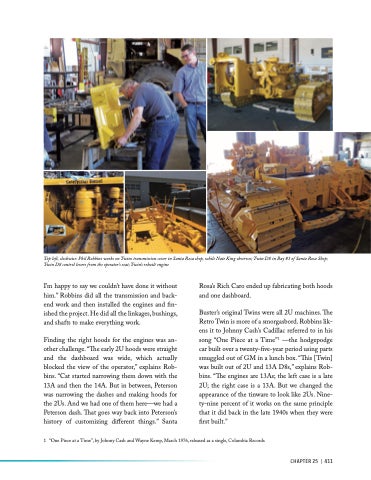

Top left, clockwise: Phil Robbins works on Twins transmission cover in Santa Rosa shop, while Nate King observes; Twin D8 in Bay #3 of Santa Rosa Shop; Twin D8 control levers from the operator’s seat; Twin’s rebuilt engine

I’m happy to say we couldn’t have done it without him.” Robbins did all the transmission and back- end work and then installed the engines and fin- ished the project. He did all the linkages, bushings, and shafts to make everything work.

Finding the right hoods for the engines was an- other challenge. “The early 2U hoods were straight and the dashboard was wide, which actually blocked the view of the operator,” explains Rob- bins. “Cat started narrowing them down with the 13A and then the 14A. But in between, Peterson was narrowing the dashes and making hoods for the 2Us. And we had one of them here—we had a Peterson dash. That goes way back into Peterson’s history of customizing different things.” Santa

Rosa’s Rich Caro ended up fabricating both hoods and one dashboard.

Buster’s original Twins were all 2U machines. The Retro Twin is more of a smorgasbord. Robbins lik- ens it to Johnny Cash’s Cadillac referred to in his song “One Piece at a Time”1 —the hodgepodge car built over a twenty-five-year period using parts smuggled out of GM in a lunch box. “This [Twin] was built out of 2U and 13A D8s,” explains Rob- bins. “The engines are 13As; the left case is a late 2U; the right case is a 13A. But we changed the appearance of the tinware to look like 2Us. Nine- ty-nine percent of it works on the same principle that it did back in the late 1940s when they were first built.”

1 “One Piece at a Time”, by Johnny Cash and Wayne Kemp, March 1976, released as a single, Columbia Records

CHAPTER 25 | 411