Page 410 - Peterson 85 Years and Going Strong

P. 410

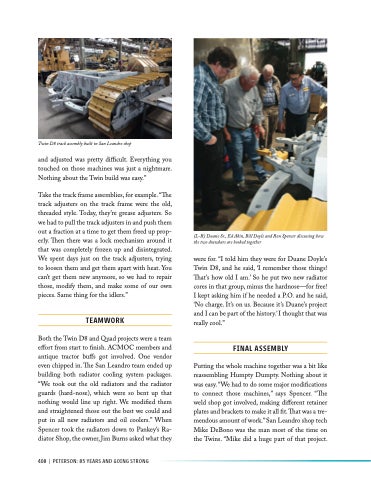

Twin D8 track assembly built in San Leandro shop

and adjusted was pretty difficult. Everything you touched on those machines was just a nightmare. Nothing about the Twin build was easy.”

Take the track frame assemblies, for example. “The track adjusters on the track frame were the old, threaded style. Today, they’re grease adjusters. So we had to pull the track adjusters in and push them out a fraction at a time to get them freed up prop- erly. Then there was a lock mechanism around it that was completely frozen up and disintegrated. We spent days just on the track adjusters, trying to loosen them and get them apart with heat. You can’t get them new anymore, so we had to repair those, modify them, and make some of our own pieces. Same thing for the idlers.”

TEAMWORK

Both the Twin D8 and Quad projects were a team effort from start to finish. ACMOC members and antique tractor buffs got involved. One vendor even chipped in. The San Leandro team ended up building both radiator cooling system packages. “We took out the old radiators and the radiator guards (hard-nose), which were so bent up that nothing would line up right. We modified them and straightened those out the best we could and put in all new radiators and oil coolers.” When Spencer took the radiators down to Pankey’s Ra- diator Shop, the owner, Jim Burns asked what they

(L-R) Duane Sr., Ed Akin, Bill Doyle and Ron Spencer discussing how the two drawbars are hooked together

were for. “I told him they were for Duane Doyle’s Twin D8, and he said, ‘I remember those things! That’s how old I am.’ So he put two new radiator cores in that group, minus the hardnose—for free! I kept asking him if he needed a P.O. and he said, ‘No charge. It’s on us. Because it’s Duane’s project and I can be part of the history.’I thought that was really cool.”

FINAL ASSEMBLY

Putting the whole machine together was a bit like reassembling Humpty Dumpty. Nothing about it was easy.“We had to do some major modifications to connect those machines,” says Spencer. “The weld shop got involved, making different retainer plates and brackets to make it all fit. That was a tre- mendous amount of work.” San Leandro shop tech Mike DeBono was the man most of the time on the Twins. “Mike did a huge part of that project.

408 | PETERSON: 85 YEARS AND GOING STRONG