Page 336 - Peterson 85 Years and Going Strong

P. 336

THE MCMURDO—SOUTH POLE TRAVERSE

The purpose of the Traverse is to transport fuel as efficiently as possible to the South Pole Station because they require diesel fuel to generate electricity. The current operation is the culmination of years of developing and refining the South Pole supply line, a 2,060-mile round trip between McMurdo and the South Pole Station.

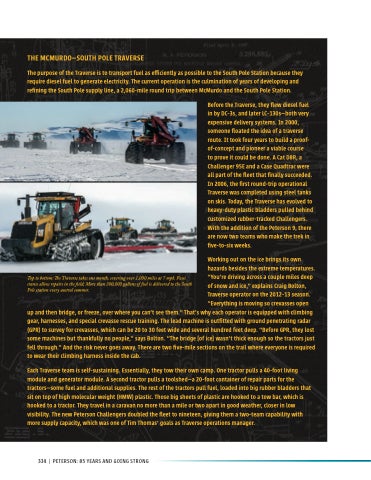

Top to bottom: The Traverse takes one month, covering over 1,000 miles at 7 mph. Fassi cranes allow repairs in the field; More than 300,000 gallons of fuel is delivered to the South Pole station every austral summer.

Before the Traverse, they flew diesel fuel in by DC-3s, and later LC-130s—both very expensive delivery systems. In 2000, someone floated the idea of a traverse route. It took four years to build a proof- of-concept and pioneer a viable course

to prove it could be done. A Cat D8R, a Challenger 95E and a Case Quadtrac were all part of the fleet that finally succeeded. In 2006, the first round-trip operational Traverse was completed using steel tanks on skis. Today, the Traverse has evolved to heavy-duty plastic bladders pulled behind customized rubber-tracked Challengers. With the addition of the Peterson 9, there are now two teams who make the trek in five-to-six weeks.

Working out on the ice brings its own hazards besides the extreme temperatures. “You’re driving across a couple miles deep of snow and ice,” explains Craig Bolton, Traverse operator on the 2012-13 season. “Everything is moving so crevasses open

up and then bridge, or freeze, over where you can’t see them.” That’s why each operator is equipped with climbing gear, harnesses, and special crevasse rescue training. The lead machine is outfitted with ground penetrating radar (GPR) to survey for crevasses, which can be 20 to 30 feet wide and several hundred feet deep. “Before GPR, they lost some machines but thankfully no people,” says Bolton. “The bridge [of ice] wasn’t thick enough so the tractors just fell through.” And the risk never goes away. There are two five-mile sections on the trail where everyone is required to wear their climbing harness inside the cab.

Each Traverse team is self-sustaining. Essentially, they tow their own camp. One tractor pulls a 40-foot living module and generator module. A second tractor pulls a toolshed—a 20-foot container of repair parts for the tractors—some fuel and additional supplies. The rest of the tractors pull fuel, loaded into big rubber bladders that sit on top of high molecular weight (HMW) plastic. Those big sheets of plastic are hooked to a tow bar, which is hooked to a tractor. They travel in a caravan no more than a mile or two apart in good weather, closer in low visibility. The new Peterson Challengers doubled the fleet to nineteen, giving them a two-team capability with more supply capacity, which was one of Tim Thomas’ goals as Traverse operations manager.

334 | PETERSON: 85 YEARS AND GOING STRONG