Page 284 - Peterson 85 Years and Going Strong

P. 284

Pretty soon Caterpillar becomes aware of it, rec- ognizes the viability of the potential market, and decides to manufacture the design themselves.” Throughout his forty years at Peterson, Ravazza has witnessed that cycle repeat itself over and over again. “We were designing and installing guarding packages on landfill machines back in the 1970s, long before Caterpillar considered it. Somewhere along the line, they recognized the demand and created an after-market package they sold under Custom Products.” The waste-handling machines Caterpillar offers today still incorporate Peterson’s original idea as a standard package.

PRODUCTION: BUCKETS AND ATTACHMENTS

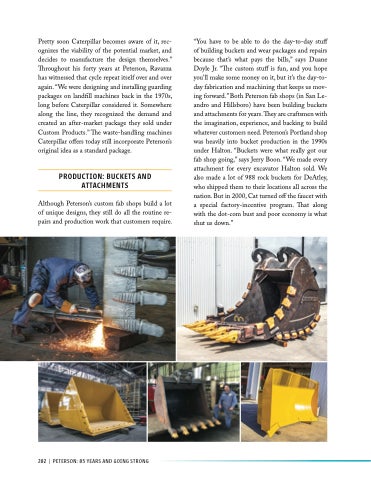

Although Peterson’s custom fab shops build a lot of unique designs, they still do all the routine re- pairs and production work that customers require.

“You have to be able to do the day-to-day stuff of building buckets and wear packages and repairs because that’s what pays the bills,” says Duane Doyle Jr. “The custom stuff is fun, and you hope you’ll make some money on it, but it’s the day-to- day fabrication and machining that keeps us mov- ing forward.” Both Peterson fab shops (in San Le- andro and Hillsboro) have been building buckets and attachments for years. They are craftsmen with the imagination, experience, and backing to build whatever customers need. Peterson’s Portland shop was heavily into bucket production in the 1990s under Halton. “Buckets were what really got our fab shop going,” says Jerry Boon. “We made every attachment for every excavator Halton sold. We also made a lot of 988 rock buckets for DeAtley, who shipped them to their locations all across the nation. But in 2000, Cat turned off the faucet with a special factory-incentive program. That along with the dot-com bust and poor economy is what shut us down.”

282 | PETERSON: 85 YEARS AND GOING STRONG