Page 281 - Peterson 85 Years and Going Strong

P. 281

PULL-THROUGH BUSINESS

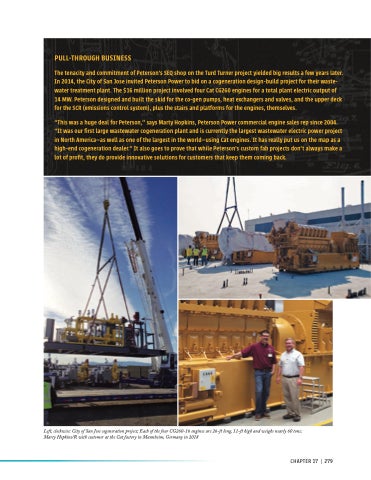

The tenacity and commitment of Peterson’s SEQ shop on the Turd Turner project yielded big results a few years later. In 2014, the City of San Jose invited Peterson Power to bid on a cogeneration design-build project for their waste- water treatment plant. The $16 million project involved four Cat CG260 engines for a total plant electric output of 14 MW. Peterson designed and built the skid for the co-gen pumps, heat exchangers and valves, and the upper deck for the SCR (emissions control system), plus the stairs and platforms for the engines, themselves.

“This was a huge deal for Peterson,” says Marty Hopkins, Peterson Power commercial engine sales rep since 2004. “It was our first large wastewater cogeneration plant and is currently the largest wastewater electric power project in North America—as well as one of the largest in the world—using Cat engines. It has really put us on the map as a high-end cogeneration dealer.” It also goes to prove that while Peterson’s custom fab projects don’t always make a lot of profit, they do provide innovative solutions for customers that keep them coming back.

Left, clockwise: City of San Jose cogeneration project; Each of the four CG260-16 engines are 26-ft long, 11-ft high and weighs nearly 60 tons; Marty Hopkins/R with customer at the Cat factory in Mannheim, Germany in 2018

CHAPTER 17 | 279