Page 198 - Peterson 85 Years and Going Strong

P. 198

factory, there were small discrepancies that could snowball into big headaches. “People have a ten- dency to think these were all the same but they’re not,” says Good. “If you cut a frame in one spot and then go to the next frame and use the same measurement to cut, it would be different. And I don’t mean by three inches—more like an eighth or three-sixteenths. They were all a little bit dif- ferent and when you’re fabricating, that makes a big difference because you’ve got to have parts that match up.”

Everything Pat Good and the weld shop did was

customized to fit. “It wasn’t like you put a piece of plate in a stamping machine and make all the panels exactly the same. Each one was handcrafted and adjusted to fit. When you customize things, you make it work. That’s what we do.”

In 2017, Ben Garner took over as lead. “We chose Ben because he’s organized, he has great attention to detail, and we needed a self-starter,” explains Dave Messier, Hillsboro service manager. “He and Pat made a great team. Our common goal was to send these out as if Caterpillar had built them. That was what made the group click.”

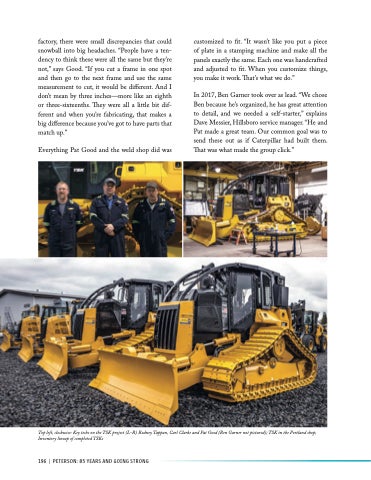

Top left, clockwise: Key techs on the TSK project (L-R) Rodney Tappan, Carl Clarke and Pat Good (Ben Garner not pictured); TSK in the Portland shop; Inventory lineup of completed TSKs

196 | PETERSON: 85 YEARS AND GOING STRONG